- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Language

Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

Fixing agents are crucial in dyeing, but in practice, they are widely used in cotton dyeing, yet rarely in polyester dyeing. This article will reveal the reasons.

Polyester (polyester fiber) is a hydrophobic fiber and is commonly dyed with disperse dyes. The dyeing process relies on high temperature and pressure (or hot melt dyeing) to allow dye molecules to penetrate into the fiber interior, achieving coloring through physical fixation (van der Waals forces, hydrogen bonds, and mechanical interlocking), rather than ionic bonding.

Cotton/linen and other cellulosic fibers mostly use reactive, direct dyes. The dye and fiber are bonded through covalent or ionic bonds, but some dyes are easily hydrolyzed and detached, requiring fixing agents to enhance fastness.

Disperse dyes exist in polyester in a crystalline or solid solution state, exhibiting high bonding strength. Under normal processing, washing and rubbing fastness are good, requiring no additional fixing.

Fixing agents are typically used to block water-soluble groups in dyes or form a thin film coating, but may affect the polyester's feel (e.g., stiffening) or cause color changes.

The crucial step in polyester dyeing is reduction washing, which aims to remove loose dye (dye that hasn't penetrated the fiber) from the fiber surface. This step is more effective than using fixing agents and directly improves wet fastness.

Most fixing agents (such as cationic ones) are designed for anionic dyes, while disperse dyes are nonionic, limiting the effectiveness of traditional fixing agents. Some special fixing agents (such as resin-based ones) may affect the hydrophobicity or heat migration properties of polyester.

If the fixing agent forms a film covering the fiber, it may hinder the unique soft and smooth feel of polyester.

During high-temperature dye heat migration (such as ironing), the fixing agent may interfere with dye stability, leading to a decrease in fastness.

For dark colors or high fastness requirements, fastness enhancers (such as polyester-specific auxiliaries) may be used, but their mechanism of action differs from traditional "fixing agents," often achieving this through dispersion protection or surface modification.

In polyester blended fabrics (such as polyester-cotton blends), the cotton component may require a color-fixing agent, in which case a product with minimal impact on the polyester will be chosen.

Sylic D2802 color-fixing agent, a textile auxiliary brand under the Skychem Group.

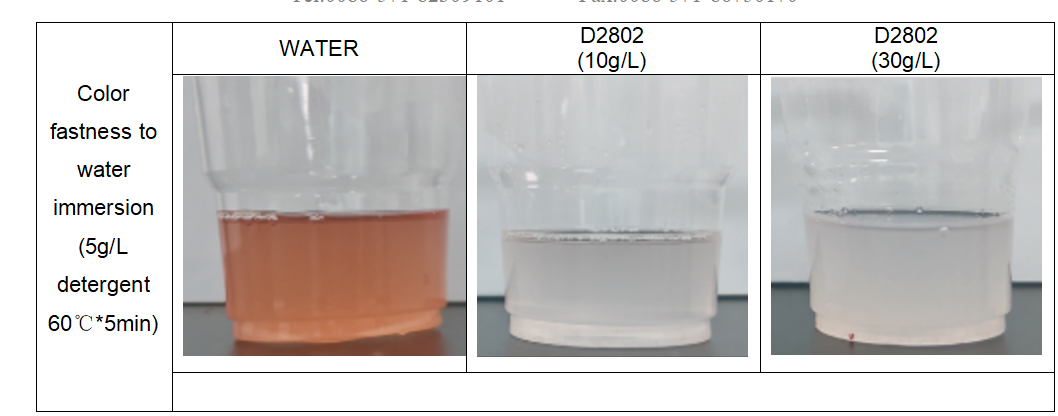

1. It can significantly improve the soaping, washing, perspiration and sea water fastness of fabrics, especially the high temperature water fastness (or boiling water fastness).

2. It can significantly improve the low and high temperature washing fastness of fabrics dyed with reactive dyes such as deep red, deep coffee, and deep black.

3. The color of the fixing agent is the same as that of the same batch of fabrics without fixing.

4. It does not affect the feel of the dyed fabric or the hydrophilicity of the fabric.

5. Does not contain free formaldehyde or bound formaldehyde.

Sylic Without Fixing Agent vs. With Sylic D2802 (CY-211HG) (watch viedo )

Sylic D2802: A high-performance fixing agent for reactive dyes.

Boosts wash fastness (even at high temperatures!)

Preserves color vibrancy without altering fabric feel.

Soaping Fastness: +40% Improvement

If you require samples, please contact info@sylicgolbal.com